Press release

Acetaldehyde Manufacturing Plant Project Report 2025: Manufacturing Plant Setup and Operations

Introduction

Acetaldehyde is one of the most important industrial chemicals and a key building block in the production of various chemicals, including acetic acid, acetic anhydride, perfumes, and plasticizers. As an essential intermediate compound, acetaldehyde finds widespread use across industries like chemicals, pharmaceuticals, food processing, and beverages. Establishing an acetaldehyde manufacturing plant can be a highly profitable venture due to its diverse applications and consistent demand in the global market. This project report will provide insights into the process of setting up an acetaldehyde manufacturing plant, from market demand to production processes, machinery requirements, and financial considerations.

Read Full Report with Table of Contents@ https://bit.ly/3CYamNr

Industry Overview

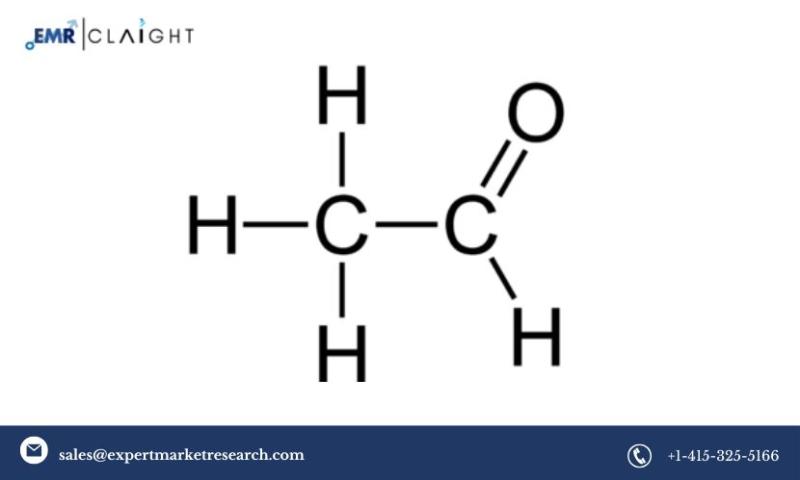

Acetaldehyde (CH3CHO) is an organic compound that appears as a colorless, flammable liquid with a pungent, fruity odor. It plays a significant role in the production of a variety of chemicals used in everyday products such as synthetic resins, solvents, plastics, and food additives.

Key Applications of Acetaldehyde:

Production of Acetic Acid: Acetaldehyde is one of the key raw materials in the manufacturing of acetic acid, which is used in food, textiles, and plastics industries.

Manufacturing of Perfumery and Flavor Compounds: Acetaldehyde is used in the production of several fragrant compounds, particularly in the fragrance and flavoring industry.

Plasticizers: Acetaldehyde serves as an intermediate in the production of plasticizers used in the manufacture of PVC and other plastics.

Pharmaceuticals: Acetaldehyde is used in the synthesis of various pharmaceutical products, including some antibiotics and sedatives.

Food Industry: Acetaldehyde is utilized as a flavoring agent in the production of beverages like fruit juices and alcoholic drinks, especially in the fermentation process.

Get a Free Sample Report with Table of Contents@ https://bit.ly/4gJgtTC

Market Demand for Acetaldehyde

The global acetaldehyde market is expected to grow steadily in the coming years due to its widespread applications and demand in various industries. Key factors driving the market growth include increasing industrialization, demand for acetic acid, and the rising use of acetaldehyde in food and beverage industries. Emerging economies in Asia-Pacific and Latin America are expected to be key growth markets for acetaldehyde due to expanding chemical industries and rising disposable income.

Key Trends in the Acetaldehyde Industry:

Growing Demand for Acetic Acid: As a key precursor to acetic acid, acetaldehyde's demand is closely tied to the expanding acetic acid industry, which is used in a wide variety of applications.

Rise in Industrial Production: The increase in industrial applications, such as plastic production and coatings, is contributing to the growing demand for acetaldehyde.

Advancements in Production Technology: Continuous advancements in production technology, including the development of more efficient catalysts, are likely to reduce production costs and improve sustainability.

Sustainability Concerns: There is a growing trend toward finding more eco-friendly and sustainable methods of acetaldehyde production, reducing the reliance on petroleum-based feedstocks.

Manufacturing Process of Acetaldehyde

Acetaldehyde can be manufactured via several methods, with the most common being the oxidation of ethanol, the dehydrogenation of ethanol, and the oxidation of hydrocarbons. Below are the main methods used for the production of acetaldehyde:

1. Oxidation of Ethanol

Process Overview: The most widely used method of acetaldehyde production involves the oxidation of ethanol in the presence of an oxidizing agent such as oxygen. This process typically takes place in the gas phase, with catalysts such as silver or copper used to enhance the reaction.

Equipment Used: The reaction is carried out in a fixed-bed reactor or a fluidized-bed reactor where ethanol is vaporized and mixed with oxygen at elevated temperatures.

2. Dehydrogenation of Ethanol

Process Overview: In this method, ethanol is dehydrogenated to acetaldehyde by removing two hydrogen atoms in the presence of a catalyst, typically copper or zinc oxide. This method is less commonly used than oxidation but is still an important process for acetaldehyde production.

Equipment Used: This process requires a high-temperature reactor to facilitate the dehydrogenation reaction.

3. Oxidation of Hydrocarbons

Process Overview: Acetaldehyde can also be produced by the oxidation of hydrocarbons like ethylene or methane in the presence of oxygen. The process is typically more complex and involves the use of specific catalysts.

Equipment Used: A continuous-flow reactor with a catalytic bed is used for the oxidation of hydrocarbons to acetaldehyde.

4. Ethylene Acetoxylation

Process Overview: In this method, ethylene is reacted with acetic acid in the presence of a catalyst to form acetaldehyde. This process is more energy-intensive than others but is useful for large-scale acetaldehyde production.

Equipment Used: The reaction is performed in a pressurized reactor with a suitable catalyst, typically at high temperatures.

Required Machinery and Equipment

To establish an acetaldehyde manufacturing plant, the following equipment is essential:

Reactors: Fixed-bed reactors, fluidized-bed reactors, or tubular reactors for the oxidation of ethanol or hydrocarbons.

Distillation Columns: Used for separating acetaldehyde from other byproducts and impurities.

Heat Exchangers: To manage the heat generated during the reaction process.

Catalysts: Copper, silver, or zinc oxide catalysts are used in the production of acetaldehyde from ethanol or hydrocarbons.

Pumps and Compressors: To transfer liquids and gases through various stages of the production process.

Storage Tanks: For storing raw materials and finished acetaldehyde before distribution.

Safety Equipment: Acetaldehyde is highly flammable, and safety equipment such as flame arrestors, explosion-proof systems, and gas detectors is necessary.

Financial Considerations

Establishing an acetaldehyde manufacturing plant requires a significant investment in infrastructure, machinery, raw materials, and labor. The following are key financial factors to consider:

1. Initial Investment Costs

Land and Building Costs: The cost of purchasing or leasing land, constructing the plant, and setting up necessary utilities (water, electricity, etc.).

Machinery Costs: Investment in reactors, distillation columns, heat exchangers, pumps, and storage tanks.

Licensing and Certification Fees: Regulatory approvals, environmental clearances, and safety certifications must be obtained before beginning operations.

Working Capital: Initial inventory of raw materials (ethanol, acetic acid, etc.) and packaging materials.

2. Operational Costs

Raw Materials: The cost of acquiring ethanol, hydrocarbons, and other chemicals used in the production process.

Labor Costs: Wages for factory workers, supervisors, quality control personnel, and administrative staff.

Utility Costs: Energy costs associated with running the manufacturing plant, including heating, cooling, and electricity.

Maintenance Costs: Ongoing maintenance of machinery and equipment to ensure smooth operation and minimize downtime.

3. Revenue Potential

Sales of Acetaldehyde: The primary revenue stream will come from selling acetaldehyde to downstream industries such as chemicals, pharmaceuticals, and food processing.

Byproducts: Byproducts like acetic acid and ethanol may also be sold, adding to revenue streams.

4. Return on Investment (ROI)

The ROI for an acetaldehyde manufacturing plant is influenced by market demand, production capacity, and cost control. It is typically expected to take 2-3 years to break even and start generating significant profits, depending on the scale and efficiency of the operation.

Regulatory and Compliance Factors

Acetaldehyde manufacturing plants must comply with various regulations related to safety, environmental protection, and quality control. Key regulations include:

Environmental Regulations: Proper waste management, emissions control, and pollution reduction measures must be in place to comply with local environmental laws.

Safety Standards: Due to the highly flammable nature of acetaldehyde, stringent safety protocols must be followed, including the installation of fire suppression systems, explosion-proof equipment, and gas detectors.

Product Quality Standards: The acetaldehyde produced must meet industry standards for purity and quality, with regular testing and certification.

Read More Reports:

Doxazosin Manufacturing Plant Project Report: https://bit.ly/4hMncNT

Creatine Monohydrate Manufacturing Plant Project Report: https://bit.ly/4bds4ZV

Eco-Friendly Car Wash Soap Manufacturing Plant Project Report: https://bit.ly/4k0d4ml

Fenofibrate Manufacturing Plant Project Report: https://bit.ly/3QnfEoS

Instant Noodles Manufacturing Plant Project Report: https://bit.ly/4k4sc1X

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist - U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

About Us:

Acquire unparalleled access to critical industry insights with our comprehensive market research reports, meticulously prepared by a team of seasoned experts. These reports are designed to equip decision-makers with an in-depth understanding of prevailing market trends, competitive landscapes, and growth opportunities.

Our high-quality, data-driven analysis provides the essential framework for organisations seeking to make informed and strategic decisions in an increasingly complex and rapidly evolving business environment. By investing in our market research reports, you can ensure your organisation remains agile, proactive, and poised for success in today's competitive market.

Don't miss the opportunity to elevate your business intelligence and strengthen your strategic planning. Secure your organisation's future success by acquiring one of our Expert Market Research reports today.

Acetaldehyde is one of the most important industrial chemicals and a key building block in the production of various chemicals, including acetic acid, acetic anhydride, perfumes, and plasticizers. As an essential intermediate compound, acetaldehyde finds widespread use across industries like chemicals, pharmaceuticals, food processing, and beverages. Establishing an acetaldehyde manufacturing plant can be a highly profitable venture due to its diverse applications and consistent demand in the global market. This project report will provide insights into the process of setting up an acetaldehyde manufacturing plant, from market demand to production processes, machinery requirements, and financial considerations.

Read Full Report with Table of Contents@ https://bit.ly/3CYamNr

Industry Overview

Acetaldehyde (CH3CHO) is an organic compound that appears as a colorless, flammable liquid with a pungent, fruity odor. It plays a significant role in the production of a variety of chemicals used in everyday products such as synthetic resins, solvents, plastics, and food additives.

Key Applications of Acetaldehyde:

Production of Acetic Acid: Acetaldehyde is one of the key raw materials in the manufacturing of acetic acid, which is used in food, textiles, and plastics industries.

Manufacturing of Perfumery and Flavor Compounds: Acetaldehyde is used in the production of several fragrant compounds, particularly in the fragrance and flavoring industry.

Plasticizers: Acetaldehyde serves as an intermediate in the production of plasticizers used in the manufacture of PVC and other plastics.

Pharmaceuticals: Acetaldehyde is used in the synthesis of various pharmaceutical products, including some antibiotics and sedatives.

Food Industry: Acetaldehyde is utilized as a flavoring agent in the production of beverages like fruit juices and alcoholic drinks, especially in the fermentation process.

Get a Free Sample Report with Table of Contents@ https://bit.ly/4gJgtTC

Market Demand for Acetaldehyde

The global acetaldehyde market is expected to grow steadily in the coming years due to its widespread applications and demand in various industries. Key factors driving the market growth include increasing industrialization, demand for acetic acid, and the rising use of acetaldehyde in food and beverage industries. Emerging economies in Asia-Pacific and Latin America are expected to be key growth markets for acetaldehyde due to expanding chemical industries and rising disposable income.

Key Trends in the Acetaldehyde Industry:

Growing Demand for Acetic Acid: As a key precursor to acetic acid, acetaldehyde's demand is closely tied to the expanding acetic acid industry, which is used in a wide variety of applications.

Rise in Industrial Production: The increase in industrial applications, such as plastic production and coatings, is contributing to the growing demand for acetaldehyde.

Advancements in Production Technology: Continuous advancements in production technology, including the development of more efficient catalysts, are likely to reduce production costs and improve sustainability.

Sustainability Concerns: There is a growing trend toward finding more eco-friendly and sustainable methods of acetaldehyde production, reducing the reliance on petroleum-based feedstocks.

Manufacturing Process of Acetaldehyde

Acetaldehyde can be manufactured via several methods, with the most common being the oxidation of ethanol, the dehydrogenation of ethanol, and the oxidation of hydrocarbons. Below are the main methods used for the production of acetaldehyde:

1. Oxidation of Ethanol

Process Overview: The most widely used method of acetaldehyde production involves the oxidation of ethanol in the presence of an oxidizing agent such as oxygen. This process typically takes place in the gas phase, with catalysts such as silver or copper used to enhance the reaction.

Equipment Used: The reaction is carried out in a fixed-bed reactor or a fluidized-bed reactor where ethanol is vaporized and mixed with oxygen at elevated temperatures.

2. Dehydrogenation of Ethanol

Process Overview: In this method, ethanol is dehydrogenated to acetaldehyde by removing two hydrogen atoms in the presence of a catalyst, typically copper or zinc oxide. This method is less commonly used than oxidation but is still an important process for acetaldehyde production.

Equipment Used: This process requires a high-temperature reactor to facilitate the dehydrogenation reaction.

3. Oxidation of Hydrocarbons

Process Overview: Acetaldehyde can also be produced by the oxidation of hydrocarbons like ethylene or methane in the presence of oxygen. The process is typically more complex and involves the use of specific catalysts.

Equipment Used: A continuous-flow reactor with a catalytic bed is used for the oxidation of hydrocarbons to acetaldehyde.

4. Ethylene Acetoxylation

Process Overview: In this method, ethylene is reacted with acetic acid in the presence of a catalyst to form acetaldehyde. This process is more energy-intensive than others but is useful for large-scale acetaldehyde production.

Equipment Used: The reaction is performed in a pressurized reactor with a suitable catalyst, typically at high temperatures.

Required Machinery and Equipment

To establish an acetaldehyde manufacturing plant, the following equipment is essential:

Reactors: Fixed-bed reactors, fluidized-bed reactors, or tubular reactors for the oxidation of ethanol or hydrocarbons.

Distillation Columns: Used for separating acetaldehyde from other byproducts and impurities.

Heat Exchangers: To manage the heat generated during the reaction process.

Catalysts: Copper, silver, or zinc oxide catalysts are used in the production of acetaldehyde from ethanol or hydrocarbons.

Pumps and Compressors: To transfer liquids and gases through various stages of the production process.

Storage Tanks: For storing raw materials and finished acetaldehyde before distribution.

Safety Equipment: Acetaldehyde is highly flammable, and safety equipment such as flame arrestors, explosion-proof systems, and gas detectors is necessary.

Financial Considerations

Establishing an acetaldehyde manufacturing plant requires a significant investment in infrastructure, machinery, raw materials, and labor. The following are key financial factors to consider:

1. Initial Investment Costs

Land and Building Costs: The cost of purchasing or leasing land, constructing the plant, and setting up necessary utilities (water, electricity, etc.).

Machinery Costs: Investment in reactors, distillation columns, heat exchangers, pumps, and storage tanks.

Licensing and Certification Fees: Regulatory approvals, environmental clearances, and safety certifications must be obtained before beginning operations.

Working Capital: Initial inventory of raw materials (ethanol, acetic acid, etc.) and packaging materials.

2. Operational Costs

Raw Materials: The cost of acquiring ethanol, hydrocarbons, and other chemicals used in the production process.

Labor Costs: Wages for factory workers, supervisors, quality control personnel, and administrative staff.

Utility Costs: Energy costs associated with running the manufacturing plant, including heating, cooling, and electricity.

Maintenance Costs: Ongoing maintenance of machinery and equipment to ensure smooth operation and minimize downtime.

3. Revenue Potential

Sales of Acetaldehyde: The primary revenue stream will come from selling acetaldehyde to downstream industries such as chemicals, pharmaceuticals, and food processing.

Byproducts: Byproducts like acetic acid and ethanol may also be sold, adding to revenue streams.

4. Return on Investment (ROI)

The ROI for an acetaldehyde manufacturing plant is influenced by market demand, production capacity, and cost control. It is typically expected to take 2-3 years to break even and start generating significant profits, depending on the scale and efficiency of the operation.

Regulatory and Compliance Factors

Acetaldehyde manufacturing plants must comply with various regulations related to safety, environmental protection, and quality control. Key regulations include:

Environmental Regulations: Proper waste management, emissions control, and pollution reduction measures must be in place to comply with local environmental laws.

Safety Standards: Due to the highly flammable nature of acetaldehyde, stringent safety protocols must be followed, including the installation of fire suppression systems, explosion-proof equipment, and gas detectors.

Product Quality Standards: The acetaldehyde produced must meet industry standards for purity and quality, with regular testing and certification.

Read More Reports:

Doxazosin Manufacturing Plant Project Report: https://bit.ly/4hMncNT

Creatine Monohydrate Manufacturing Plant Project Report: https://bit.ly/4bds4ZV

Eco-Friendly Car Wash Soap Manufacturing Plant Project Report: https://bit.ly/4k0d4ml

Fenofibrate Manufacturing Plant Project Report: https://bit.ly/3QnfEoS

Instant Noodles Manufacturing Plant Project Report: https://bit.ly/4k4sc1X

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist - U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

About Us:

Acquire unparalleled access to critical industry insights with our comprehensive market research reports, meticulously prepared by a team of seasoned experts. These reports are designed to equip decision-makers with an in-depth understanding of prevailing market trends, competitive landscapes, and growth opportunities.

Our high-quality, data-driven analysis provides the essential framework for organisations seeking to make informed and strategic decisions in an increasingly complex and rapidly evolving business environment. By investing in our market research reports, you can ensure your organisation remains agile, proactive, and poised for success in today's competitive market.

Don't miss the opportunity to elevate your business intelligence and strengthen your strategic planning. Secure your organisation's future success by acquiring one of our Expert Market Research reports today.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage

to this press release on woodPRI. woodPRI disclaims liability for any content contained in

this release.

Recommend

/newsMicroencapsulation Market Deep Analysis on Key Players - Dow Corning, Encapsys, Syngenta Crop Protection, Evonik Industries, 3M and Bayer

Market Study Report Adds Global Microencapsulation Market Size, Status and Forecast 2024 added to its database. The report provides key statistics on the current state of the industry and other analytical data to understand the market.

Extensive research is required for choosing the appropriate cor...

/newsGermany Airbag Market Size 2023: Global Share, Industry And Report Analysis By 2030 | Hyundai Mobis Co., Ltd. Key Safety Systems, Inc. Robert Bosch GmbH

Germany airbag market is expected to grow at a CAGR of around 6% during the forecast period. Germany Airbag Market research report refers to gathering and analyzing significant market data serve as best medium for various industry players to launch novel product or service. It is vital for key firms...

/newsSecurities Brokerages And Stock Exchanges Market Outlook 2021: Big Things are Happening

A new intelligence report released by HTF MI with title "Global Securities Brokerages And Stock Exchanges Market Survey & Outlook" is designed covering micro level of analysis by Insurers and key business segments, offerings and sales channels. The Global Securities Brokerages And Stock Exchange...

/newsRenewable Chemicals Market Emerging Trends and Competitive Landscape Forecast to 2028

The renewable chemicals market was valued at US$ 80,566.30 million in 2021 and is projected to reach US$ 1,76,750.76 million by 2028 it is expected to grow at a CAGR of 11.9% from 2021 to 2028. The research report focuses on the current market trends, opportunities, future potential of the market, a...

/newsHow Coronavirus is Impacting Cold Brew Coffee, Global Market Volume Analysis, Size, Share and Key Trends 2020-2026

"Market Latest Research Report 2020:

Los Angles United States, February 2020: The Cold Brew Coffee market has been garnering remarkable momentum in the recent years. The steadily escalating demand due to improving purchasing power is projected to bode well for the global market. QY Research's lates...

/newsCorporate E-Learning Market - Global Industry Size, Share, Key Players Analysis that are Infor, SkillSoft Corporation, Adrenna, CERTPOINT Systems and others with Regional Forecast to 2022

Overview:

E-Learning is used to enhance the learning procedures for newer job requirements and to make employees sound about the internal and external changes in the market and respective organizations. This method has created considerable differences in the ways of training and developing employee...