Press release

Overcoming the foremost Common Misconceptions of Lubrication

After working closely with industrial personnel, we came across a few misconceptions about lubrication in equipment. These point are worth noticing as it carries significant economic losses to industries. By overcoming them, the industrial facilities can gain tremendous monetary profit and opportunities while greatly enhancing profitability and operational excellence.

1. Lubrication of industrial equipment is of less consequence:

The misinterpretation says that lubrication plays a minor role in industrial facilities and after effects are not major and therefore it doesn't require any special attention.

Now let's understand what research says. As per the research conducted in industries, major maintenance costs sum up of repairing of friction and mechanical wear on equipment approx 6 % of GDP Gross domestic product.

If we do a root cause analysis for mechanical wear, the cause is inadequate lubrication or a wrong lubricant. Studies have proven that improper lubrication leads to approx 43% of mechanical failures, 54% bearing failures, and 70% equipment failures.

Equipment lubrication is a common problem and vital as well. Many intermediate losses are occurring, but our immediate concern is losses due to inadequate lubrication. One should consider the cost behind the replacement of bearing in terms of cost of bearing as well as labour cost. The cost involved in emergency shutdowns due to equipment failure, maintenance cost, energy cost.

[Fact] Rather than being of less consequence, lubrication of industrial equipment has a symbolic impact on operational excellence

2. Lubrication of equipment is an easy job:

The misinterpretation says that lubrication of equipment is an easy job and doesn't require any skill. After all, oil is oil and grease is grease. Do you feel it's right???

Here comes in the picture the five rights of lubrication i.e the right lubricant in the right place in the right amount at the right time using the right procedure. It sounds simple, but is it???

The complexity of the statement increases when the parameters of equipment come into the picture, working conditions, and many other industrial factors.

Eg: We can start with a question

How much equipment are there in a plant which requires lubrication?

The next question that comes is which component e.g. bearing, shaft, chain drives, couplings, etc. Now working parameters and conditions and the right lubricant are selected.

In the same way, we have to consider all the five rights of lubrication. Now maybe it doesn't sound that simple. The long lubricant in at the wrong place at the wrong time can create havoc in machines and equipment failure leading to production losses.

[Fact] In contradiction to the impression that its simple, lubrication of industrial equipment is a detailing and complex process

3. Cutting down lubrication costs by avoiding lubricating of equipment:

The misinterpretation says that we can easily cut off the lubrication cost from budget

In industries, the maintenance people are in aim to lower the maintenance budget. The quote believed in maintenance is "do more with less" but instead can't we do more with what we have? Here the lubrication plays a vital role.

With an optimized lubrication solution, industrial facilities can minimize unplanned downtime and eliminate the primary cause of equipment failure leading to an increase in higher productivity from existing assets and personnel.

[Fact] Instead of cutting down on lubrication cost, proper equipment lubrication offers a substantial opportunity.

4. Lubrication is key for achieving operational excellence and profitability

Here, we all have to give a thought to which lubrication misconception is creating havoc in your operations? It's worth your time to find the answers. Considering lubrication issues can provide the industrial plant with significant financial opportunities and return on investment.

Remember lubrication is 100% proactive maintenance

Plot no. A-791, 3, MIDC Industrial Area, Navi Mumbai,

Email digital@mosil.com

Mosil Lubricant

We believe that the best way to achieve sustainable success as a group is to

act in the long-term interests of our shareholders, partners and society.

Experience working with us and witness how we become part of your process,

how we understand your points, aspirations and start living your life.

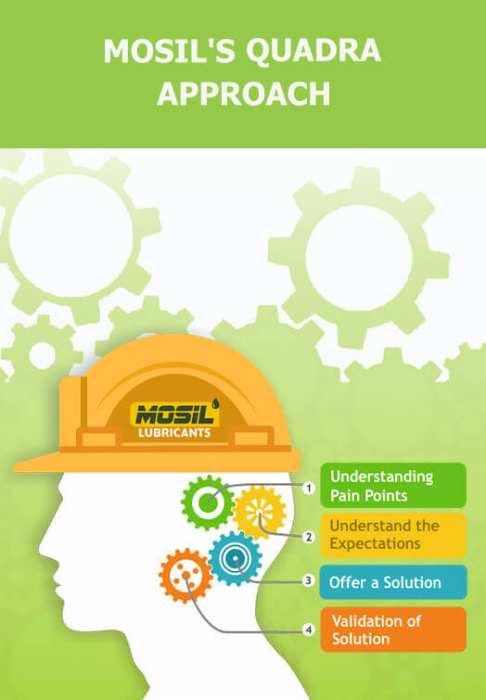

Thanks to our systematic Quadra Approach that guides us to develop a perfect lubrication solution that can smoothen out all the roughs without

creating avoidable friction to other operations.

1. Lubrication of industrial equipment is of less consequence:

The misinterpretation says that lubrication plays a minor role in industrial facilities and after effects are not major and therefore it doesn't require any special attention.

Now let's understand what research says. As per the research conducted in industries, major maintenance costs sum up of repairing of friction and mechanical wear on equipment approx 6 % of GDP Gross domestic product.

If we do a root cause analysis for mechanical wear, the cause is inadequate lubrication or a wrong lubricant. Studies have proven that improper lubrication leads to approx 43% of mechanical failures, 54% bearing failures, and 70% equipment failures.

Equipment lubrication is a common problem and vital as well. Many intermediate losses are occurring, but our immediate concern is losses due to inadequate lubrication. One should consider the cost behind the replacement of bearing in terms of cost of bearing as well as labour cost. The cost involved in emergency shutdowns due to equipment failure, maintenance cost, energy cost.

[Fact] Rather than being of less consequence, lubrication of industrial equipment has a symbolic impact on operational excellence

2. Lubrication of equipment is an easy job:

The misinterpretation says that lubrication of equipment is an easy job and doesn't require any skill. After all, oil is oil and grease is grease. Do you feel it's right???

Here comes in the picture the five rights of lubrication i.e the right lubricant in the right place in the right amount at the right time using the right procedure. It sounds simple, but is it???

The complexity of the statement increases when the parameters of equipment come into the picture, working conditions, and many other industrial factors.

Eg: We can start with a question

How much equipment are there in a plant which requires lubrication?

The next question that comes is which component e.g. bearing, shaft, chain drives, couplings, etc. Now working parameters and conditions and the right lubricant are selected.

In the same way, we have to consider all the five rights of lubrication. Now maybe it doesn't sound that simple. The long lubricant in at the wrong place at the wrong time can create havoc in machines and equipment failure leading to production losses.

[Fact] In contradiction to the impression that its simple, lubrication of industrial equipment is a detailing and complex process

3. Cutting down lubrication costs by avoiding lubricating of equipment:

The misinterpretation says that we can easily cut off the lubrication cost from budget

In industries, the maintenance people are in aim to lower the maintenance budget. The quote believed in maintenance is "do more with less" but instead can't we do more with what we have? Here the lubrication plays a vital role.

With an optimized lubrication solution, industrial facilities can minimize unplanned downtime and eliminate the primary cause of equipment failure leading to an increase in higher productivity from existing assets and personnel.

[Fact] Instead of cutting down on lubrication cost, proper equipment lubrication offers a substantial opportunity.

4. Lubrication is key for achieving operational excellence and profitability

Here, we all have to give a thought to which lubrication misconception is creating havoc in your operations? It's worth your time to find the answers. Considering lubrication issues can provide the industrial plant with significant financial opportunities and return on investment.

Remember lubrication is 100% proactive maintenance

Plot no. A-791, 3, MIDC Industrial Area, Navi Mumbai,

Email digital@mosil.com

Mosil Lubricant

We believe that the best way to achieve sustainable success as a group is to

act in the long-term interests of our shareholders, partners and society.

Experience working with us and witness how we become part of your process,

how we understand your points, aspirations and start living your life.

Thanks to our systematic Quadra Approach that guides us to develop a perfect lubrication solution that can smoothen out all the roughs without

creating avoidable friction to other operations.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage

to this press release on woodPRI. woodPRI disclaims liability for any content contained in

this release.

Recommend

/newsMicroencapsulation Market Deep Analysis on Key Players - Dow Corning, Encapsys, Syngenta Crop Protection, Evonik Industries, 3M and Bayer

Market Study Report Adds Global Microencapsulation Market Size, Status and Forecast 2024 added to its database. The report provides key statistics on the current state of the industry and other analytical data to understand the market.

Extensive research is required for choosing the appropriate cor...

/newsGermany Airbag Market Size 2023: Global Share, Industry And Report Analysis By 2030 | Hyundai Mobis Co., Ltd. Key Safety Systems, Inc. Robert Bosch GmbH

Germany airbag market is expected to grow at a CAGR of around 6% during the forecast period. Germany Airbag Market research report refers to gathering and analyzing significant market data serve as best medium for various industry players to launch novel product or service. It is vital for key firms...

/newsSecurities Brokerages And Stock Exchanges Market Outlook 2021: Big Things are Happening

A new intelligence report released by HTF MI with title "Global Securities Brokerages And Stock Exchanges Market Survey & Outlook" is designed covering micro level of analysis by Insurers and key business segments, offerings and sales channels. The Global Securities Brokerages And Stock Exchange...

/newsRenewable Chemicals Market Emerging Trends and Competitive Landscape Forecast to 2028

The renewable chemicals market was valued at US$ 80,566.30 million in 2021 and is projected to reach US$ 1,76,750.76 million by 2028 it is expected to grow at a CAGR of 11.9% from 2021 to 2028. The research report focuses on the current market trends, opportunities, future potential of the market, a...

/newsHow Coronavirus is Impacting Cold Brew Coffee, Global Market Volume Analysis, Size, Share and Key Trends 2020-2026

"Market Latest Research Report 2020:

Los Angles United States, February 2020: The Cold Brew Coffee market has been garnering remarkable momentum in the recent years. The steadily escalating demand due to improving purchasing power is projected to bode well for the global market. QY Research's lates...

/newsCorporate E-Learning Market - Global Industry Size, Share, Key Players Analysis that are Infor, SkillSoft Corporation, Adrenna, CERTPOINT Systems and others with Regional Forecast to 2022

Overview:

E-Learning is used to enhance the learning procedures for newer job requirements and to make employees sound about the internal and external changes in the market and respective organizations. This method has created considerable differences in the ways of training and developing employee...